The world of amber resin has long fascinated scientists and collectors alike, not only for its aesthetic beauty but also for its remarkable durability. Among the many challenges faced in preserving amber's pristine condition, yellowing stands out as a persistent issue. Recent advancements in anti-yellowing experiments have shed new light on how to maintain the integrity of this ancient material, offering promising solutions for both conservationists and commercial applications.

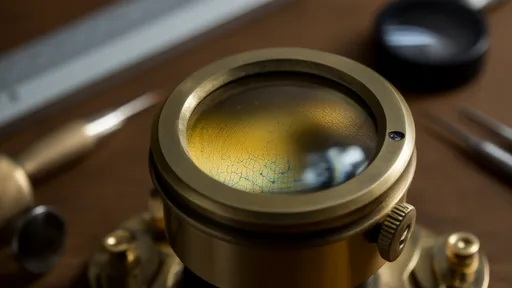

Amber, a fossilized tree resin, is prized for its warm hues and organic origins. However, over time, exposure to environmental factors such as light, heat, and oxygen can cause the resin to undergo chemical changes, leading to discoloration. This yellowing effect not only diminishes the visual appeal of amber but can also affect its value. Researchers have been working tirelessly to understand the mechanisms behind this phenomenon and develop effective countermeasures.

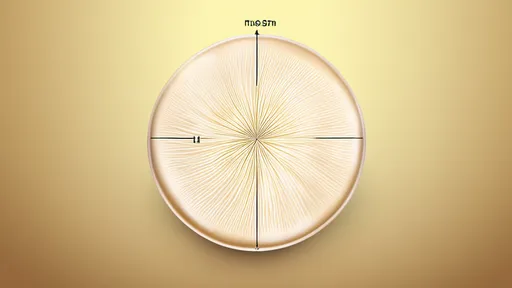

One of the most groundbreaking studies in this field involves the use of advanced spectroscopic techniques to analyze the molecular structure of amber before and after exposure to yellowing-inducing conditions. By identifying the specific chemical bonds that break down during the yellowing process, scientists have been able to pinpoint the root causes of the discoloration. This knowledge has paved the way for targeted interventions that can slow or even prevent the degradation of the resin.

Innovative treatments have emerged from these findings, including the application of specialized coatings that act as barriers against harmful environmental factors. These coatings are designed to be optically transparent, ensuring that the natural beauty of the amber remains unaffected while providing robust protection. Early results from laboratory tests have been highly encouraging, with treated samples showing significantly less yellowing compared to untreated controls over extended periods.

Another promising avenue of research focuses on modifying the resin's composition at the molecular level. By introducing stabilizing agents during the polymerization process, scientists have created synthetic amber analogs that exhibit enhanced resistance to yellowing. These engineered materials not only mimic the appearance and properties of natural amber but also offer superior longevity, making them ideal for applications where durability is paramount.

The implications of these anti-yellowing experiments extend far beyond the realm of jewelry and collectibles. Museums and cultural heritage institutions stand to benefit greatly from these advancements, as they grapple with the challenge of preserving amber artifacts for future generations. Additionally, industries that utilize amber-derived materials, such as certain types of varnishes and adhesives, may find these innovations invaluable in improving product performance and lifespan.

Field testing of these new anti-yellowing technologies is currently underway in various climates and conditions to assess their real-world efficacy. Preliminary data suggests that the treatments hold up well under diverse environmental stresses, though long-term monitoring will be essential to confirm their durability. Researchers are particularly interested in how these solutions perform in tropical regions, where high humidity and intense sunlight pose significant challenges to amber preservation.

As the science of amber conservation continues to evolve, collaboration between chemists, material scientists, and conservators has become increasingly important. This interdisciplinary approach has already yielded significant breakthroughs and is expected to drive further innovation in the coming years. The shared goal is not only to prevent yellowing but to develop a comprehensive understanding of amber's aging process, enabling more effective preservation strategies across the board.

The commercial potential of these anti-yellowing technologies is substantial, with growing interest from both the luxury goods market and industrial sectors. Manufacturers of high-end amber products are particularly keen to incorporate these advancements, as they could significantly enhance the value proposition of their offerings. Meanwhile, industrial users see potential for cost savings through extended product lifecycles and reduced maintenance requirements.

Looking ahead, researchers are exploring the possibility of adapting these anti-yellowing techniques for other types of natural resins and polymers that face similar degradation challenges. The fundamental insights gained from studying amber could have far-reaching applications in materials science, potentially leading to more durable plastics, coatings, and composite materials. This cross-pollination of ideas between traditional craftsmanship and modern science exemplifies the exciting possibilities at this intersection of disciplines.

Public awareness of these developments remains relatively limited, but educational initiatives are beginning to bridge this gap. Museums and scientific institutions are incorporating information about amber preservation into their exhibits and outreach programs, helping visitors appreciate not just the beauty of these organic gems but also the sophisticated science behind their conservation. This growing understanding may lead to increased support for research in this niche but important field.

The journey from ancient tree resin to modern scientific marvel continues to unfold, with each discovery adding new chapters to amber's remarkable story. As anti-yellowing experiments push the boundaries of what's possible in resin preservation, they remind us of the enduring connection between nature's creations and human ingenuity. The future of amber looks brighter—and decidedly less yellow—thanks to these pioneering efforts.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025