The global electroplating industry is undergoing a transformative shift with the introduction of the new ISO-2024 standard for cyanide-free plating adhesion. This long-awaited benchmark represents a culmination of years of research, testing, and industry collaboration to establish rigorous performance criteria for environmentally conscious metal finishing processes.

For decades, cyanide-based electroplating solutions dominated industrial applications due to their exceptional throwing power and adhesion characteristics. However, growing environmental concerns and tightening regulations have forced manufacturers to seek safer alternatives. The ISO-2024 standard finally provides clear guidelines for evaluating the adhesion performance of cyanide-free plating systems, creating a level playing field for sustainable surface treatment technologies.

Technical Breakthroughs in Adhesion Testing

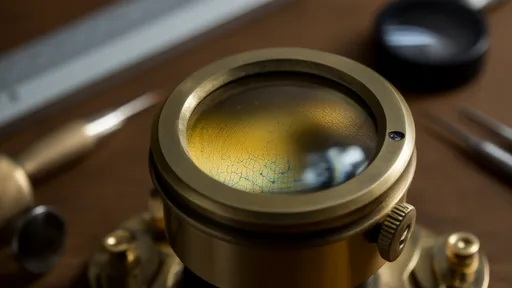

The heart of the ISO-2024 standard lies in its comprehensive approach to adhesion assessment. Traditional peel tests and cross-cut methods have been enhanced with advanced quantitative measurement techniques. The new protocol incorporates environmental stress testing, including thermal cycling and humidity exposure, to simulate real-world conditions more accurately than previous standards.

Perhaps most significantly, the standard introduces a revolutionary electrochemical impedance spectroscopy (EIS) method for evaluating the metal-substrate interface integrity. This non-destructive technique allows for in-process quality control without damaging finished components, representing a major advancement for production efficiency.

Environmental Impact and Industry Response

Environmental groups have praised the ISO-2024 standard as a watershed moment for sustainable manufacturing. By eliminating cyanide from the plating process while maintaining robust adhesion performance, the standard addresses two critical industry challenges simultaneously. Early adopters report significant reductions in hazardous waste treatment costs and improved workplace safety metrics.

Major automotive and electronics manufacturers have already begun requiring suppliers to certify compliance with ISO-2024. This rapid adoption reflects both regulatory pressures and growing consumer demand for environmentally responsible products. Industry analysts predict the standard will become the de facto global benchmark within two years, potentially rendering older adhesion standards obsolete.

Implementation Challenges and Solutions

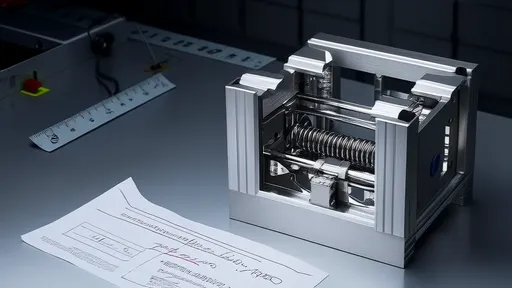

Transitioning to cyanide-free plating processes under the new standard hasn't been without hurdles. Many facilities report initial difficulties achieving consistent adhesion on complex geometries that were easily handled by cyanide baths. The industry has responded with innovative chemistry solutions, including advanced complexing agents and pulse-reverse plating techniques that improve throwing power.

Equipment manufacturers have also stepped up with new rectifier technologies that provide superior current distribution, along with advanced filtration systems to maintain bath purity. These technological synergies are helping manufacturers not only meet but exceed the adhesion requirements set forth in ISO-2024.

The research community continues to push boundaries, with several universities and corporate labs developing next-generation additives that promise to further bridge the performance gap between cyanide and cyanide-free systems. These developments suggest that ISO-2024 may represent just the beginning of a new era in sustainable metal finishing.

As implementation progresses, the standard is already sparking innovation across the supply chain. From novel pretreatment processes to advanced quality control systems, the plating industry is experiencing a renaissance of technological advancement driven by environmental responsibility and performance excellence.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025