In the world of fine jadeite jewelry and carvings, preservation is paramount. For centuries, artisans and collectors have relied on waxing techniques to protect the stone’s luster and prevent surface damage. However, the growing awareness of chemical exposure risks has sparked a shift toward safer alternatives—specifically, the use of food-grade wood wax as a replacement for industrial wax formulations.

Industrial waxes, though effective in creating a glossy finish, often contain synthetic additives and solvents that may compromise both human health and the integrity of the jadeite over time. Restorers and conservators have reported instances of wax residues yellowing or becoming tacky, attracting dust and requiring aggressive cleaning methods that can scratch the stone. In contrast, food-grade wood wax, derived from natural plant oils and beeswax, offers a non-toxic solution that aligns with modern sustainability standards while maintaining the stone’s brilliance.

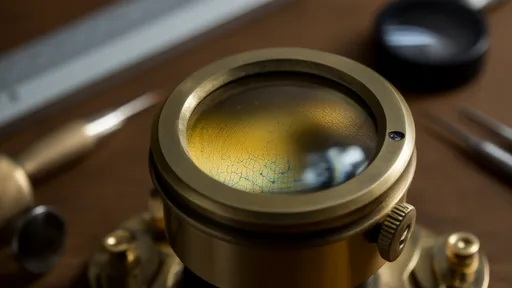

The science behind this transition is rooted in material compatibility. Jadeite, a dense and porous gemstone, benefits from a wax that penetrates microscopically without leaving surface buildup. Food-grade wood waxes, designed for cutting boards and children’s toys, possess a low melting point that allows for gentle application with a lint-free cloth. Unlike petroleum-based industrial waxes, they don’t require heat guns or chemical strippers for removal—a simple buffing with a bamboo fiber cloth restores the finish.

Collectors in Southeast Asia, where jadeite heirlooms are often passed down through generations, have pioneered this method. Workshops in Myanmar’s jade markets now advocate for beeswax blends infused with camellia oil, a traditional preservative that enhances water resistance. This hybrid approach not only safeguards the stone but also honors cultural practices, merging ancestral knowledge with contemporary safety concerns.

Critics initially questioned the durability of organic waxes, citing their softer consistency. Yet field tests in humid climates have disproven these claims. When applied biannually, food-grade formulations outperform industrial counterparts in preventing moisture ingress—a critical factor for jadeite stored in tropical regions. The wax’s natural viscosity adapts to temperature fluctuations, reducing the risk of cloudiness or cracking that plagues synthetic coatings.

Beyond preservation, the ethical implications resonate with younger buyers. Millennial and Gen Z collectors increasingly prioritize transparency in gemstone maintenance, rejecting harsh chemicals in favor of USDA-certified ingredients. Auction houses have taken note: Christie’s 2023 catalog for Asian artifacts explicitly mentions the use of plant-based waxes in pre-sale preparations, a first for the industry.

Practical adoption does require technique adjustments. Conservators stress the importance of pre-cleaning with distilled water (never ultrasonic baths) to remove old wax layers. The new wax should be applied in circular motions, left to cure for 24 hours, then polished to a satin sheen. This meticulous process, while time-intensive, prevents the streaking common with industrial products.

As the movement gains momentum, laboratories are developing specialized blends. A Hong Kong-based research team recently patented a jadeite-specific formula combining candelilla wax with antioxidant-rich green tea extract, designed to slow oxidative discoloration in untreated stones. Such innovations signal a broader trend: the convergence of gemology and green chemistry, where age-old materials meet cutting-edge science.

The implications extend beyond jadeite. Lapidaries working with other porous stones like turquoise and malachite are experimenting with similar substitutions. What began as a niche practice in jade conservation may well redefine mineral care standards across the decorative arts. For now, one truth remains self-evident—the marriage of safety and efficacy in food-grade wood wax presents not just an alternative, but an advancement in the art of preservation.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025