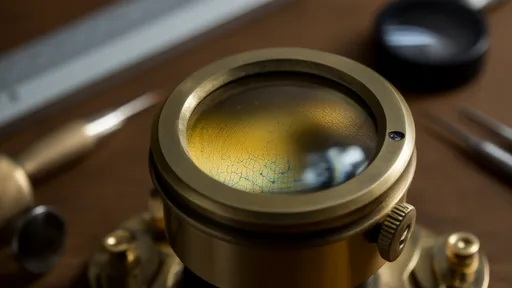

In the world of precision engineering and high-performance mechanical systems, the ability to withstand extreme conditions is not just a luxury—it’s a necessity. One of the most critical tests for evaluating the durability of components like magnetic shock-resistant bezels is the 10G acceleration impact test. This rigorous assessment pushes materials and designs to their limits, ensuring they can survive the harshest environments without compromising functionality. The results of such tests often determine whether a component is fit for aerospace, military, or industrial applications where failure is not an option.

The 10G acceleration impact test simulates sudden, high-force shocks that a component might experience during operation. For magnetic shock-resistant bezels, this is particularly relevant because these parts are often used in environments where vibrations, drops, or collisions are common. The test involves subjecting the bezel to a force equivalent to ten times the acceleration due to gravity (10G), which can reveal weaknesses in design, material integrity, or assembly methods. Engineers meticulously analyze the data to identify any deformations, cracks, or performance degradation that could compromise the bezel’s effectiveness in real-world scenarios.

Material selection plays a pivotal role in passing the 10G acceleration impact test. Advanced alloys, composite materials, and specialized coatings are often employed to enhance the bezel’s ability to absorb and dissipate energy. For instance, certain high-strength polymers or titanium alloys can provide the necessary toughness while keeping the weight manageable. The magnetic properties of the bezel must also remain stable under impact, as any disruption could affect its functionality in applications like precision instrumentation or secure mounting systems.

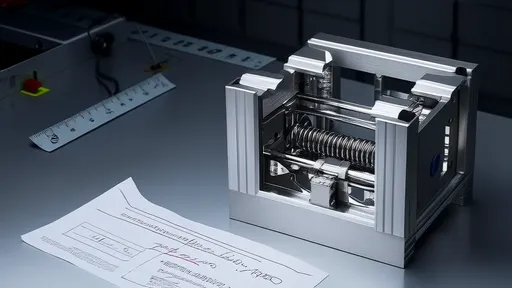

Beyond material science, the design of the bezel itself is a critical factor. Engineers use finite element analysis (FEA) and computational modeling to predict how the bezel will behave under extreme stress. These simulations help optimize the shape, thickness, and structural reinforcements to ensure the bezel can endure the 10G impact without failure. Features like shock-absorbing grooves, reinforced edges, or modular construction can significantly improve performance. The goal is to create a bezel that not only survives the test but also maintains its precision and reliability over time.

The testing process itself is a meticulous endeavor. High-speed cameras, accelerometers, and strain gauges are used to capture every detail of the impact event. Data is collected at microsecond intervals to provide a comprehensive understanding of how the bezel responds to the shock. Post-test inspections include microscopic examinations to detect micro-fractures or material fatigue that might not be visible to the naked eye. Only after passing these exhaustive evaluations can a magnetic shock-resistant bezel be certified for use in critical applications.

In industries like aerospace and defense, the stakes are incredibly high. A bezel that fails under impact could lead to catastrophic equipment malfunction or even endanger lives. This is why the 10G acceleration impact test is more than just a checkbox—it’s a validation of engineering excellence. Companies that invest in these rigorous testing protocols demonstrate their commitment to quality and reliability, setting themselves apart in competitive markets.

Looking ahead, advancements in materials and testing technologies will continue to raise the bar for magnetic shock-resistant bezels. Innovations like self-healing materials or adaptive damping systems could further enhance performance, making these components even more resilient. As industries demand higher standards, the 10G acceleration impact test will remain a cornerstone of quality assurance, ensuring that only the toughest and most reliable bezels make it into the field.

The journey from concept to certified product is fraught with challenges, but it’s a necessary path for those who prioritize durability and precision. For engineers and manufacturers, the 10G acceleration impact test is not just a hurdle—it’s an opportunity to prove that their designs can withstand whatever the world throws at them. And for end-users, it’s the assurance that the technology they rely on won’t let them down when it matters most.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025